HAZET IMPACT WRENCH APPLICATION FIELDS

POWERFUL LOOSENING WITH PNEUMATIC TOOLS

Impact wrenches are used wherever you need to loosen or tighten screw connections. They shine especially when it comes to stubborn screw connections which are very hard to loosen – for example, if they are exposed to the weather and get stuck. HAZET impact wrenches can take care of just about any stuck screw, thanks to their high loosening torque and impact function.

Impact wrenches are known for their use on tyres – and not just on passenger cars, but also on agricultural machinery such as tractors. In those cases, the larger devices with an output of 20 mm (3/4 inch) or higher are used.

But HAZET also provides additional impact wrench variants for a wide range of tasks. The best-selling 9012 M-1 and its companions 9011 M and 9012 MTT, for example, are short devices perfectly suited to confined working spaces.

KEEP ONE HAND FREE

OPERATION OF THE IMPACT WRENCH

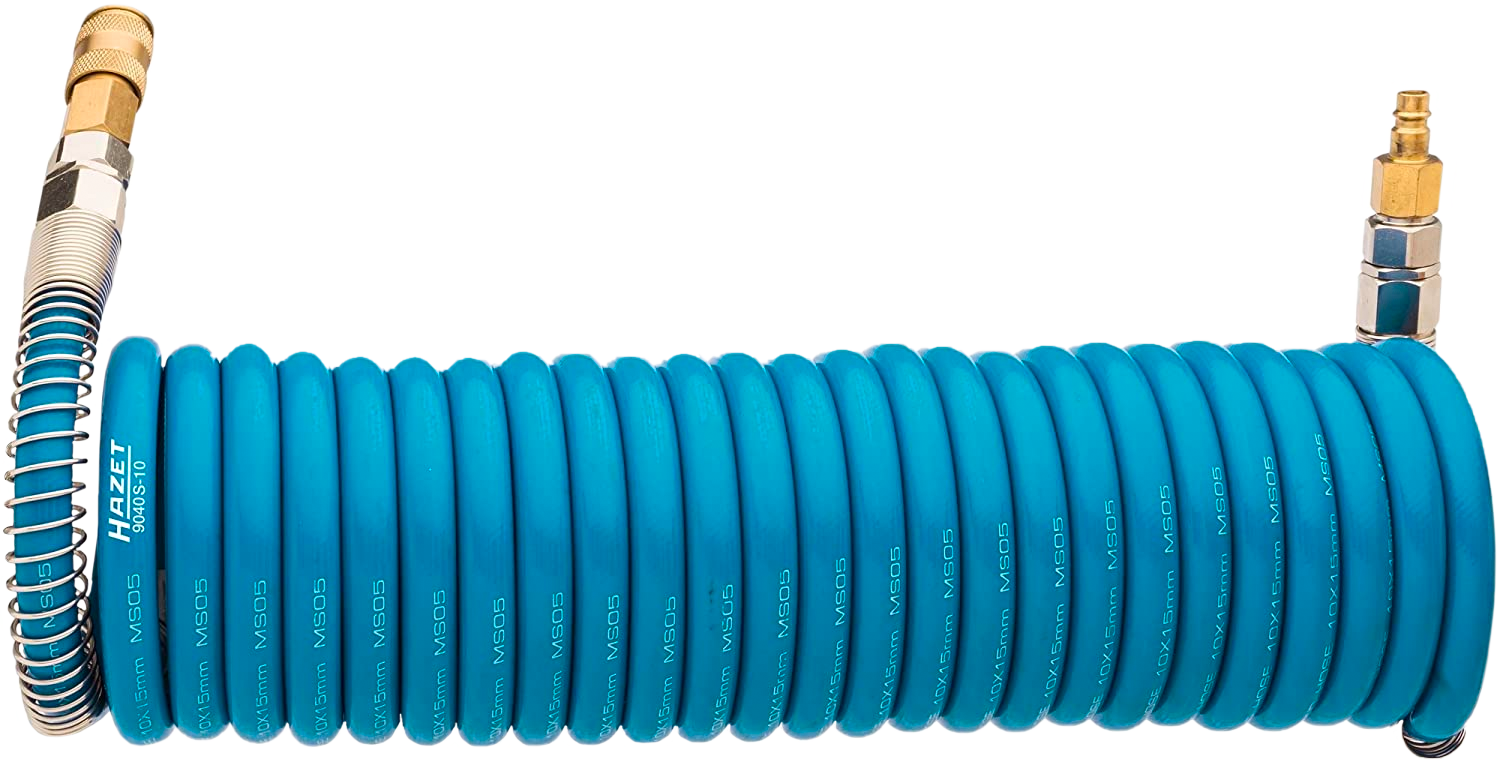

The right coupler plug for your HAZET impact wrench is always included in delivery. You can get started right away with the coupler plug, a compressed air hose and a compressor with sufficient volume.

HAZET impact wrenches generally have two directions of movement: reverse for loosening screw connections, forward for tightening screws. In the forward direction, you can measure out the tightening power. The tightening torque depends on various factors such as working pressure, inner hose diameter/hose length and screw-joint.

A large proportion of the HAZET impact wrenches feature one-hand operation. This is a great advantage because it allows you to switch the device's direction of movement while keeping one hand free. This helps you out, for example, when changing the tyres, where you can hold the tyre still with one hand while comfortably switching the direction of the impact wrench.

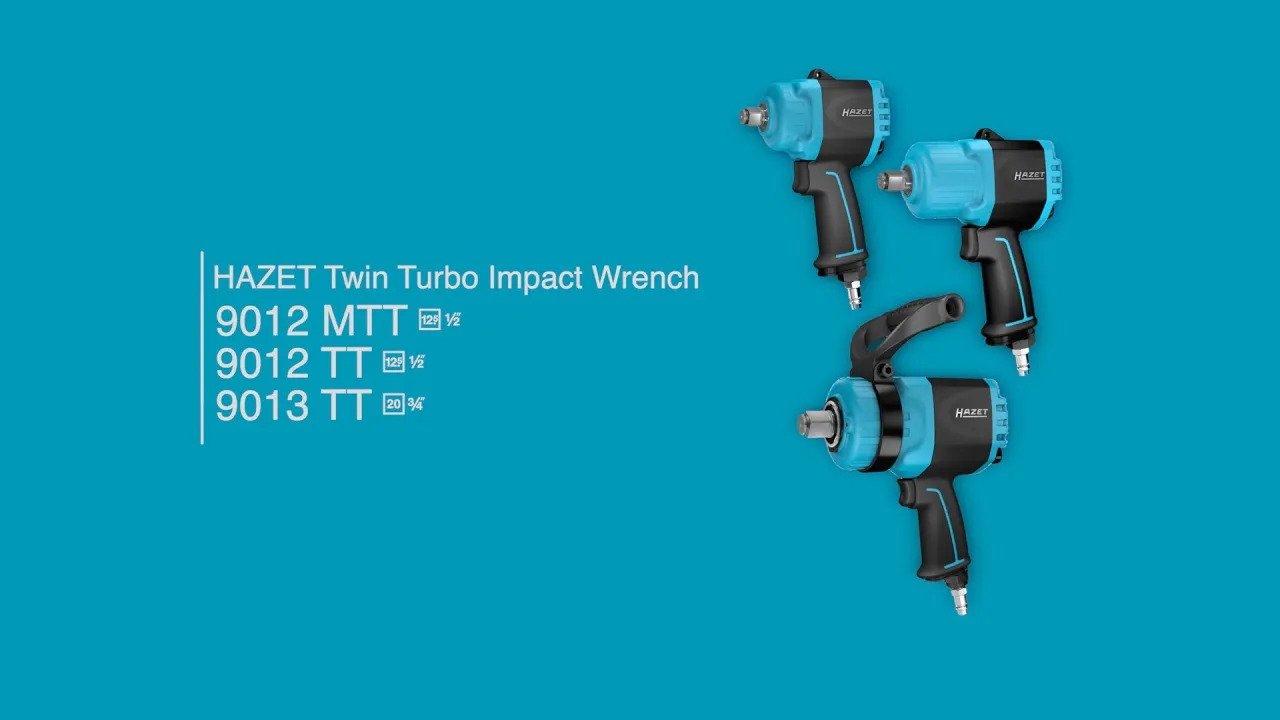

DOUBLE-PACKED POWER

INNOVATIVE TWIN TURBO TECHNOLOGY

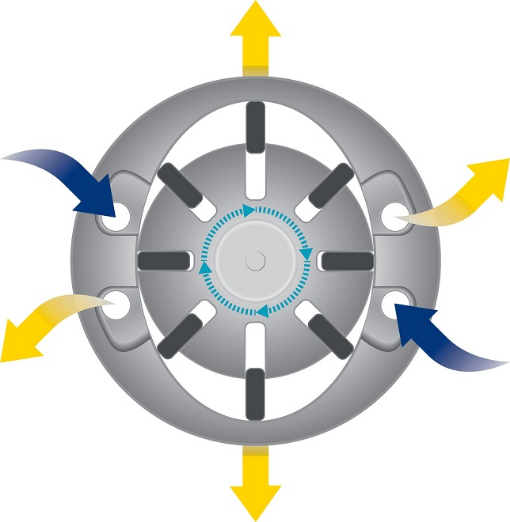

The new HAZET Twin Turbo impact wrenches provide a big boost in loosening power with a quicker build-up of power. Two air inlets and four air outlets – that's double the number of inlets and outlets on the average impact wrench on the market – ensure that capacity is higher and the maximal loosening power is reached more quickly.

Two air inlets and four air outlets ensure enormous power and a quicker build-up.

Highlights of the Twin Turbo series

- Innovative 8-blade motor with 25 % higher impact performance ensures high maximum torque

- Long service life and high efficiency in industrial and automotive applications

- Higher power makes loosening of screw connections quicker, saving time and money

THE FANTASTIC FOUR: OUR STRIKING MECHANISM TOOLS

THE STRIKING MECHANISM

The striking mechanism is a crucial component of the impact wrench. The striking mechanism hits the screw. The hammers or pegs (depending on the type of striking mechanism) are driven by the rotor and sit directly in front of the square output.

HAZET uses four types of striking mechanisms which differ in their functions and have special advantages:

| Operation | Advantages |

| Two metal pins generate the strike driven by a cam in an axial direction | This striking mechanism builds up pressure quickly (is agile), and is lightweight and cost effective |

| Operation | Advantages |

| Two hammers generate the strike with opposing pendulum movements | This striking mechanism generates a powerful strike, has a very long service life and produces little vibration |

| Operation | Advantages |

| One hammer generates the impact as with the twin hammer mechanism | This striking mechanism allows for a low weight and an especially short striking mechanism with a long service life |

| Operation | Advantages |

| Direct force transmission without a hammer | This striking mechanism reduces vibrations and damage to the tool thanks to the direct force transmissions |

SPARE PARTS AT A GLANCE

SPARE PARTS SHOP

HAZET impact wrenches are extremely sturdy and designed for everyday use in the workshop. If any individual parts of your impact wrench become defective, you can replace some of them by yourself. To find the right part for your impact wrench, you can take a look at the relevant spare part lists and download them here.

First and foremost, oil protects against corrosion. Compressed air contains moisture which can corrode and damage the internal parts of the impact wrench, so the parts should always be lubricated with oil. Oil also helps the blades to move smoothly.

The parts – especially the inside of the housing, which the blades go along – corrode until they break. These then need to be replaced prematurely (unnecessary costs), or in the worst case scenario, the device may be irreparable.

Every day, after you have used them. If you know that the device is no longer being used, then it should be oiled again before being put away.

Put a few drops into the air inlet, and let the device run for 3 seconds while holding a towel on the air outlet to catch any escaping excess oil.

The HAZET maintenance units 9070-2 (1/2") and 9070-4 (1/4") are ideally suited to oiling pneumatic devices, each consisting of a filter-pressure reducer, an oil-mist lubricator and a manometer.

Special pneumatic oil which should at least be resin- and acid-free. HAZET pneumatic oil is silicone-free, too. That's why we recommend the HAZET pneumatic oil 9400 (available in 100 ml or 1000 ml containers) for optimal operation.

IT GOES DOWN LIKE OIL

HAZET 9400-100 SPECIAL PNEUMATIC TOOL OIL

The silicone-free special oil reduces wear to the air motor and ensures top performance with daily use. The special oil can be applied cleanly using the nozzle with screw cap. This also makes it perfectly suitable for impact wrenches and significantly increases machine service life. The filling capacity is 100 ml.

WORKS WITH HIGH PRESSURE

COMPRESSOR AND COMPRESSED AIR

A compressor is an absolute must when working with pneumatic devices. In the first instance, the performance of the tools used depends on the compressor. The deciding factors are the volume of the boiler and the feed rate of the compressor. Keep in mind that feed rate information for a compressor is usually indicated without pressure. This means that the air volume generated with a working pressure of 6.3 bar is significantly lower.

For our expert tools, we recommend a minimum boiler volume of 150 litres, so the impact wrench can reach its full potential.

It is also important to observe the working pressure to reach this full potential. High pressure leads to a disproportionate level of wear and does not increase the performance by much, because the devices are optimised to a certain working pressure.

Working at a high pressure also carries the risk of impact with the hose, and makes an unpleasantly loud banging sound when disconnecting the hose. To combat this, HAZET recommends a safety coupling which is easy to operate and which depressurises the device before removing the hose, preventing the bang and the hose impact.

| Model | Working pressure | Air requirement |

| 9011M | 6,3 bar | 85,2 l/min |

| 9012SPC | 6,3 bar | 127,4 l/min |

| 9012-1SPC | 6,3 bar | 127 l/min |

| 9012M | 6,3 bar | 127 l/min |

| 9012MT | 6,3 bar | 135 l/min |

| 9012EL-SPC | 6,3 bar | 139 l/min |

| 9012M-PD | 6,3 bar | 127 l/min |

| 9013M | 6,3 bar | 153 l/min |

| 9013SPC | 6,3 bar | 176 l/min |

| 9013MG | 6,3 bar | 198 l/min |

| 9012A-1 | 6,3 bar | 113 l/min |

| 9012M-1 | 6,3 bar | 127,4 l/min |

| 9014MG-1 | 6,3 bar | 271 l/min |

| 9014P-1 | 6,3 bar | 283 l/min |

HAZET SAFETY COUPLINGS PRODUCT PRESENTATION

Safety comes first! Dangerous hose impact is a thing of the past with the HAZET series 9000 safety couplings. The safety coupling depressurises the connection before decoupling, removing the chance of an unwanted disconnection. Michael Paetsch from HAZET product management can tell you how it works.

1. Size

2. Output